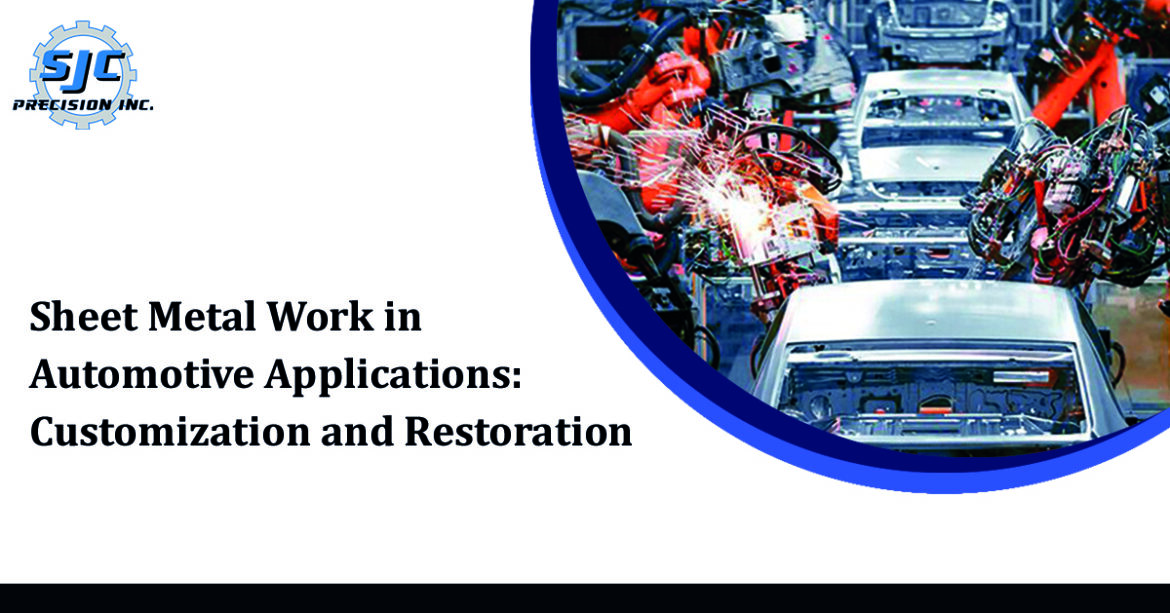

In automotive customization and restoration, sheet metal work is crucial in transforming vehicles into stunning works of art. The demand for customized and restored automobiles has increased from classic car enthusiasts to modern car fans. If you’re looking to amplify the appearance and performance of your vehicle, sheet metal work offers a range of possibilities. In this blog, we will deliver the world of sheet metal services in automotive applications, highlighting its significance and the various techniques involved.

Understanding Sheet Metal Work

Sheet metal work involves the shaping, forming, and fabricating of metal sheets to create desired components for automotive applications. This process requires skilled craftsmanship, attention to detail, and a deep understanding of the vehicle’s structure. Sheet metal workers utilize various tools and techniques to shape metal sheets, including cutting, bending, welding, and soldering.

The Importance of Sheet Metal Services

Sheet metalwork is not only about aesthetics but also plays a vital role in a vehicle’s overall functionality and structural integrity. Well-executed sheet metal work can enhance aerodynamics, improve performance, and ensure the durability of automotive components. Whether repairing damaged panels, creating custom body kits, or restoring vintage cars, skilled sheet metal workers are indispensable in the automotive industry.

Customization through Sheet Metal Services

One of the most exciting aspects of sheet metal work in automotive applications is the ability to customize vehicles according to individual preferences. Customization allows car enthusiasts to express their unique style and create an attractive vehicle. Sheet metal work enables the fabrication of custom body panels, fenders, hoods, and other exterior components, providing endless design possibilities.

Restoration with Sheet Metal Services

Restoring vintage automobiles to their former glory requires meticulous attention to detail and exceptional sheet metal work. Many classic cars suffer from rust, corrosion, and structural damage. Sheet metal workers skilled in automotive restoration can recreate original body panels, repair damaged sections, and ensure historical accuracy during restoration. The art of preserving automotive history through sheet metal work is a remarkable feat that requires expertise and passion.

Techniques in Sheet Metal Services

Cutting and Shaping

The first step in sheet metal work involves cutting and shaping the metal sheets to match the desired design & can be done by using various tools, such as electric shears, nibblers, or plasma cutters. Precision and accuracy are crucial during this stage to ensure seamless integration with the vehicle’s existing components.

Bending and Forming

Bending and forming metal sheets require specialized tools like brakes, rollers, and hammers. Skilled sheet metal workers can manipulate the metal to achieve smooth curves, sharp angles, and complex shapes. This step is crucial for creating custom body panels, fenders, and other intricate components.

Welding and Soldering

Welding and soldering are essential techniques in sheet metal work used to join metal pieces securely. Whether it’s MIG welding, TIG welding, or soldering, the welds’ quality dramatically influences the finished product’s durability and longevity. Experienced sheet metal workers ensure precise welds and seamless joints to maintain the vehicle’s structural integrity.

Surface Preparation and Finishing

To achieve a perfect final product, sheet metal components undergo surface preparation and finishing. This includes sanding, grinding, and applying various coatings, such as primers, paints, or protective finishes. The surface finish enhances the visual appeal and protects the metal from corrosion and environmental factors.

The Advantages of Professional Sheet Metal Services

Opting for professional sheet metal work in automotive applications offers numerous advantages for vehicle owners. Let’s explore some of the

important benefits:

1. Superior Craftsmanship

Professional sheet metal workers possess the expertise and experience to deliver superior craftsmanship. They deeply understand metalworking techniques and can execute precise cuts, bends, and welds. Their attention to detail ensures that every component fits seamlessly and optimally within the vehicle.

2. Customization Options

Working with a skilled sheet metal worker opens up a world of customization possibilities. Whether you want to modify your vehicle’s exterior, create a unique body kit, or design custom interior panels, a professional can bring your vision to life. They can collaborate with you to understand your preferences and translate them into stunning metal creations that reflect your individuality.

3. Enhanced Durability

Sheet metal work contributes significantly to automotive components’ durability and structural integrity. When done professionally, the fabricated parts are built to last. High-quality materials and precise manufacturing techniques ensure that the components can withstand the rigors of daily use, including exposure to varying weather conditions, road debris, and other environmental factors.

4. Restoring Automotive Classics

For enthusiasts passionate about classic cars, sheet metal work is crucial in restoration. Vintage vehicles often require extensive repairs and corroded or damaged body panel replacement. Professional sheet metal workers possess the knowledge and skill to recreate original parts or repair existing ones, ensuring an authentic restoration that preserves the historical value and aesthetics of the vehicle.

5. Increased Resale Value

Investing in professional sheet metal work can significantly increase the resale value of your vehicle. Customized cars and well-restored classics tend to attract attention and command higher prices. The meticulous attention to detail, superior craftsmanship, and unique design elements from professional sheet metal work can make your vehicle a sought-after gem among collectors and enthusiasts alike.

6. Seamless Integration

Whether adding aftermarket components or restoring a vintage vehicle, professional sheet metal work ensures seamless integration with the existing structure. The fabricated parts blend harmoniously with the rest of the vehicle, maintaining its original aesthetics and functionality. This precise attention to detail gives the impression that the modifications or repairs are a natural extension of the vehicle’s design, enhancing its overall appeal.

7. Safety and Structural Integrity

Automotive components fabricated through professional sheet metal work meet strict safety standards. These components are designed and manufactured with the vehicle’s structural integrity, ensuring they provide the necessary support and protection. Professional sheet metal workers use industry-standard techniques and materials to guarantee the safety of the vehicle’s occupants.

By choosing professional Sheet Metal Services, you can access customization options that allow you to express your unique style and create a vehicle that stands out from the crowd. Moreover, professional sheet metal workers’ expertise and precision contribute to your vehicle’s increased resale value, making it a desirable asset among automotive enthusiasts.

Investing in professional sheet metal services enhances your vehicle’s visual appeal and ensures its safety and structural integrity. The meticulous fabrication techniques, high-quality materials, and seamless integration with the existing structure guarantee a long-lasting and reliable automotive component.

So, if you’re passionate about automotive customization or embarking on a classic car restoration project, consider the expertise of professional Sheet Metal Services like SJC Precision. Their skills and knowledge can turn your automotive dreams into reality, creating a vehicle that reflects your vision and surpasses your expectations.