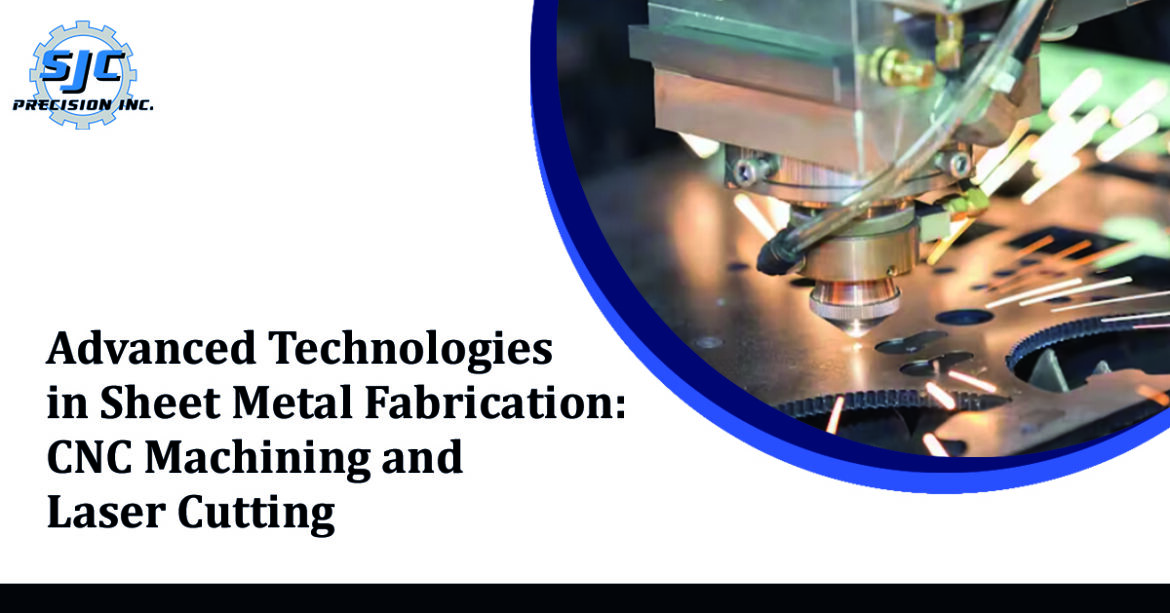

Sheet metal fabrication is an essential or primary process in the manufacturing industry that involves cutting, shaping, and molding thin metal sheets into various products. Over the years, technology has continued to advance, bringing about more efficient and effective sheet metal fabrication methods. Two such advanced technologies in sheet metal fabrication are CNC machining and laser cutting.

CNC machining and laser cutting have revolutionized the sheet metal fabrication industry, making it possible to produce high-quality metal products with greater precision and speed. This blog will provide a detailed guide to these two advanced technologies in sheet metal fabrication, highlighting their features, advantages, and applications.

What is CNC Machining?

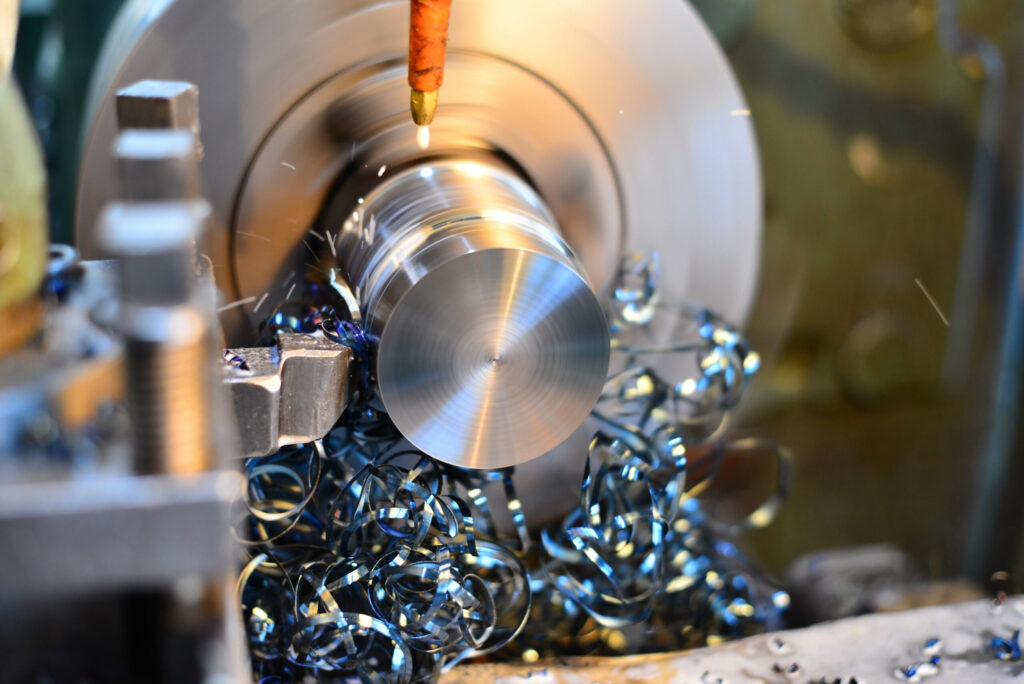

CNC machining refers to using computer numerical control (CNC) machines to automate the process of cutting, drilling, and shaping metal sheets into precise shapes and sizes. CNC machines use a set of instructions, usually in the form of a computer program, to control the movement of cutting tools and other machinery. This process ensures the cuts are precise and accurate, reducing errors and minimizing waste. CNC machining is highly versatile and can fabricate a wider range of sheet metal products, including brackets, enclosures, and electrical cabinets.

The Advantages of CNC Machining

CNC machining offers several advantages over traditional sheet metal fabrication methods. One significant advantage is its ability to produce highly accurate and consistent parts. CNC machines can perform the same tasks repeatedly with the same level of precision, ensuring that each product is identical to the others. CNC machines can also be programmed to produce complex shapes & designs that would be impossible to achieve using traditional sheet metal fabrication methods. Additionally, CNC machining reduces the waste material generated during fabrication, resulting in lower costs and greater efficiency.

What is Laser Cutting?

Laser cutting is another advanced technology used in sheet metal fabrication. This process involves using a high-powered laser beam to cut through metal sheets quickly and accurately. The laser beam is directed by a computer program that controls its intensity and movement, allowing it to cut through metal sheets of varying thicknesses and shapes. Laser cutting is highly precise and can produce intricate designs & shapes that would be impossible or difficult to achieve using other cutting methods.

The Advantages of Laser Cutting

Laser cutting offers several advantages over traditional cutting methods. One significant advantage is its ability to cut through a wide range of materials, including steel, aluminum, and copper, with high precision and accuracy. Laser cutting also produces clean and smooth cuts that require minimal post-processing, reducing production time and costs. Laser cutting is highly flexible and can be used to cut materials of varying thicknesses and shapes, making it ideal for a wide range of sheet metal fabrication applications.

Integrating CNC Machining and Laser Cutting

Integrating CNC machining and laser cutting in sheet metal fabrication has revolutionized the industry. Combining these two technologies offers advantages, including high precision and accuracy, increased productivity, and cost-effectiveness.

CNC machines can be programmed to work with laser cutting technology, allowing for more complex shapes and designs. This integration also reduces the need for additional machining processes, leading to faster production times and increased productivity.

Using CNC machines and laser cutting technology in sheet metal fabrication also reduces material waste, enabling manufacturers to optimize material usage and cut sheets with minimal scrap. This reduction in waste translates to cost savings, which can be passed on to customers.

Applications of CNC Machining and Laser Cutting

CNC machining and laser cutting are widely used in various sheet metal fabrication applications, including:

- The applications of CNC machining and laser cutting in sheet metal fabrication are vast. These technologies are used in various industries, including aerospace, automotive, construction, electronics, and medical equipment.

- In the aerospace industry, CNC machining and laser cutting are used to produce aircraft parts with high precision and accuracy. The automotive industry uses these technologies to manufacture parts such as exhaust systems & body panels. In construction, CNC machines and laser cutting technology are used to create architectural features such as metal facades and cladding.

- In the electronics industry, CNC machining and laser cutting are used to manufacture components such as heat sinks and enclosures. Medical equipment manufacturers also use these technologies to create medical devices such as implants and surgical instruments.

Conclusion

CNC machining and laser cutting are two advanced technologies significantly transforming the sheet metal fabrication industry. These technologies offer many benefits, such as precision, accuracy, speed, flexibility, and cost-effectiveness. With CNC machining and laser cutting, manufacturers can produce high-quality sheet metal products quickly and efficiently, which is essential in today’s fast-paced manufacturing industry. The applications of these technologies are vast, ranging from aerospace to architecture, and they continue to expand.

It is evident that CNC machining and laser cutting are here to stay and will continue to play a significant role in the sheet metal fabrication industry. Manufacturers who incorporate these advanced technologies in their production processes can stay competitive and meet the demands of their customers. As technology continuously advances, it is exciting to anticipate what innovations will emerge and how they will shape the future of sheet metal fabrication.

SJC Precision: Enhancing Businesses through CNC Machining and Laser Cutting

SJC Precision offers valuable services in CNC machining and laser cutting, benefiting businesses in various ways. With our CNC machining expertise, we provide accurate and precise manufacturing solutions, enabling businesses to create complex parts with high efficiency and quality. Our laser-cutting capabilities allow for precise and intricate cuts on various materials, offering product design and customization versatility. By leveraging SJC Precision’s services, businesses can enhance their production processes, improve product quality, and achieve faster turnaround times, ultimately driving overall operational success.