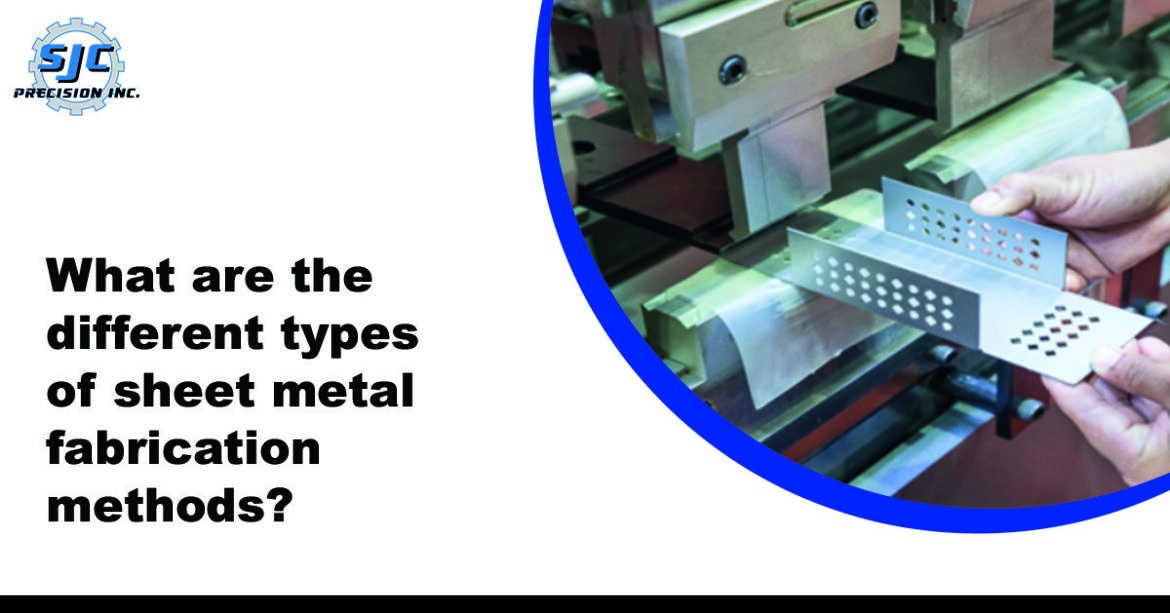

Sheet metal fabrication transforms flat metal sheets into complex shapes and structures through various forming and cutting techniques. It is an essential aspect of modern manufacturing and construction, playing a crucial role in various industries, including aerospace, automotive, medical, and consumer goods.

This blog will explore the different types of sheet metal fabrication methods, their working principles, and their applications to help you better understand this vital aspect of modern manufacturing by sheet metal fabricators.

Stamping

Stamping, also known as pressing, is a sheet metal fabrication method that involves using a press machine to shape metal into a desired form. The process involves the placement of a flat metal sheet on a die and applying force through a punch to shape the metal into the desired form.

One of the advantages of stamping is its ability to produce high-volume, consistent, and accurate parts quickly and efficiently. Stamping is also ideal for creating complex shapes, including curves and angles, with minimal waste and cost.

Stamping is widely used in various automotive, electronics, and appliance industries. For example, in the automotive industry, stamping is used to create body panels, engine components, and other parts for vehicles. In this industry of sheet metal fabricators, stamping creates metal enclosures for electronic devices.

Bending

Bending is a sheet metal fabrication method that uses a bending machine to shape metal into a desired form by applying pressure along a straight axis. The process starts with a flat metal sheet that is placed between a punch and a die, and the punch applies force to the metal, causing it to bend to a specific angle.

One of the advantages of bending is its ability to create intricate and complex shapes that would otherwise be difficult to achieve through other fabrication methods. Bending also offers a high degree of precision and control, allowing sheet metal fabricators manufacturers to produce parts with tight tolerances and consistent quality.

Bending is widely used in various industries, including construction, aerospace, and automotive. For example, in the construction industry, bending is used to create structural supports and beams. In aerospace, bending creates airframe components, including fuselage sections and wing spars. In the automotive industry, bending creates chassis components, suspension parts, and body panels.

For additional information on the tools available from sheet metal fabricators like SJC Precision, click here.

Cutting

Cutting is a fabrication method that involves the separation of metal into specific shapes and sizes through cutting tools and machines. The process can be performed using several techniques, including sawing, shearing, laser cutting, plasma cutting, and water jet cutting.

One of the advantages of cutting is its ability to create precise cuts and shapes, allowing manufacturers to produce parts with tight tolerances and consistent quality. Cutting is also a cost-effective method for producing low to medium-volume parts and is ideal for producing irregular shapes and patterns.

Cutting is widely used in various industries, including construction, aerospace, and automotive. For example, in the construction industry, cutting is used to create metal components for buildings and structures. In the aerospace industry, cutting is used to create airframe components, including fuselage sections and wing spars. In the automotive industry, cutting creates chassis components, suspension parts, and body panels.

Welding

Welding is a sheet metal fabrication method that uses heat and pressure to join two or more metal pieces into a single structure. The process can be performed using several techniques, including arc welding, gas welding, resistance welding, and laser welding.

One of the advantages of welding is its ability to create solid and permanent joints between metal components, making it ideal for creating structural components and high-stress applications. Welding is also a flexible method that allows manufacturers to join dissimilar metals, making it ideal for repairing and restoring metal components.

Welding is widely used in various industries, including construction, aerospace, and automotive. For example, in the construction industry, welding is used to create steel structures, including bridges and buildings. In aerospace, welding creates airframe components, including fuselage sections and wing spars. In the automotive industry, welding creates chassis components, suspension parts, and body panels.

Punching

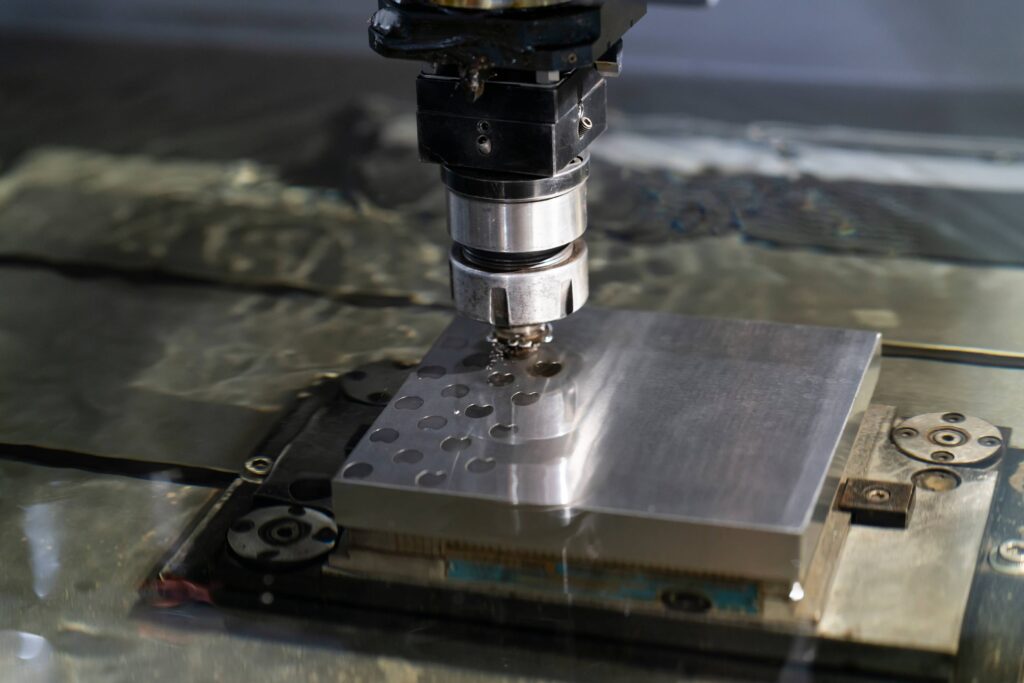

Punching is a sheet metal fabrication method that uses a punch press to create holes or cutouts in metal sheets. The process involves the placement of a flat metal sheet on a die and using a punch to apply force to the metal, cutting it into the desired shape.

One of the advantages of punching is its ability to produce high-volume, consistent, and accurate holes and cutouts quickly and efficiently. Punching is also ideal for creating complex shapes and patterns, including round, square, and rectangular holes, with minimal waste and cost.

Punching is widely used in various electronics, appliances, and automotive industries. For example, in the electronics industry, punching is used to create metal enclosures for electronic devices, including holes for buttons, switches, and connectors. In the automotive industry, punching is used to create body panels, engine components, and other vehicle parts.

How SJC Precision (Sheet Metal Fabricators) Helps in Sheet Metal Fabrication

SJC Precision is a leading sheet metal fabricator & provider of sheet metal fabrication services, offering a wide range of fabrication methods to meet the needs of various industries. The company leverages state-of-the-art technology and equipment to deliver high-quality, precise, and cost-effective metal components.

SJC Precision helps its customers in several ways regarding sheet metal fabrication. Firstly, the company has extensive experience and expertise in metal fabrication, which enables it to offer expert advice and guidance to its customers on the best fabrication methods for their specific needs.

Secondly, SJC Precision invests in cutting-edge technology and equipment to provide its customers with the most efficient and effective fabrication solutions. For example, the company uses laser cutting machines, punch presses, and other advanced fabrication equipment to produce precise and accurate metal components quickly and efficiently.

Thirdly, SJC Precision is committed to providing high-quality customer service and support, ensuring that its customers receive their metal components on time and to the highest standards. The company has a team of experienced engineers and technicians who work closely with customers to understand their requirements and provide customized fabrication solutions that meet their specific needs.

In conclusion, SJC Precision is a reliable and experienced sheet metal fabricator and provider of sheet metal fabrication services that leverage state-of-the-art technology and equipment to deliver high-quality, precise, and cost-effective metal components with excellent customer service and support.