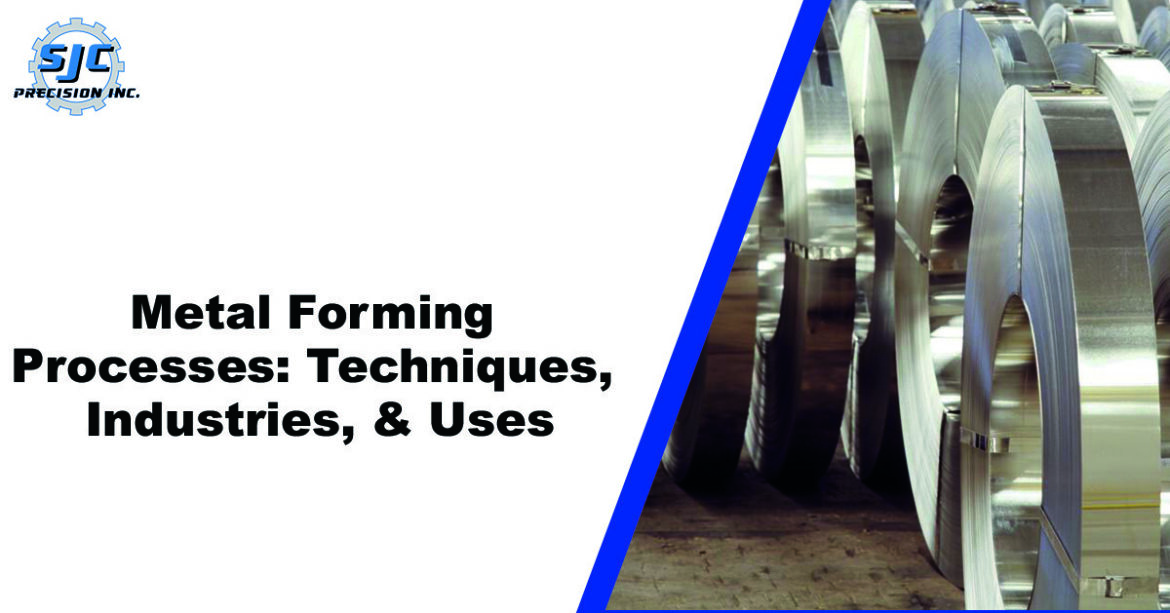

Metal forming Processes is a manufacturing process that involves shaping and reshaping metal into a desired shape or form. Metal forming is an essential industry and is the backbone of global industrial manufacturing in many aspects. Every year, dozens of millions of tons of material are used in metal-forming processes, which are believed to account for 15% to 20% of the GDP of industrialized countries. This process can be accomplished through various techniques, each with its own unique advantages and disadvantages. This blog will explore the most common metal-forming processes, the industries that use them, and the types of products that can be created.

Metal Forming Processes: Techniques

- One of the most widely used metal-forming processes is Stamping. This process involves a stamping press to press a flat metal sheet into a desired shape. The press is equipped with a die shaped like the final product, and the metal sheet is placed between the die and the press. The die forces the metal into the desired shape when the press is activated. Stamping is a fast and efficient process that is used to create a wide range of products, from automotive parts and household items to medical devices and electronics.

- Another popular metal-forming process is Forging. This process involves heating a piece of metal to its plastic state and then shaping it into the desired shape. The metal is placed between two dies and then struck with a hammer or press to reshape it. Forging is a robust and durable process that is often used to create products that will be subjected to high stress or heavy loads, such as gears, shafts, and other machine parts. (Metal Forming Processes)

- A third typical metal-forming process is Rolling. This process involves passing a piece of metal through a series of rollers, which shape the metal into the desired shape. Rolling is a very efficient process that is used to create long, thin products such as sheet metal, bars, and rods.

- A fourth process is known as Extrusion; it is a method in which a piece of metal is forced through a die to create a desired shape. The process is similar to squeezing toothpaste out of a tube. Extrusion is often used to create long, thin products such as pipes, tubes, and rods.

- A fifth process is known as Bending; it is a method in which a piece of metal is bent into a desired shape. This process can be done with a press brake machine. Bending is often used to create brackets, frames, and other structural components.

- A sixth process, known as Drawing, is a process in which a piece of metal is pulled through a die to create a desired shape. The process is similar to pulling taffy candy. Drawing is often used to create products such as cups, cans, and other hollow objects.

- A seventh process is known as deep Drawing, it is a variation of the drawing process, but it is used to create deep, hollow parts such as sinks, pans, and other objects with deep recesses.

Each of these metal forming processes has unique advantages and disadvantages, and the best process for a given application will depend on the product’s specific requirements. For example, stamping is a fast and efficient process that is well-suited to creating a wide range of products, but it may need to be more vital for products subjected to high stress or heavy loads. In contrast, forging is a solid and durable process that is ideal for creating products that will be subjected to high stress or heavy loads, but it may not be as efficient as stamping for creating a wide range of products.

Metal Forming Processes: Industries, & Uses

Metal forming is used in a wide range of industries, each with its specific uses. Some of the most common industries that use metal forming processes include:

- Automotive: Metal forming is used to create a wide range of parts for the automotive industry, including engine components, body panels, and suspension parts.

- Aerospace: Metal forming is used to create parts for planes, helicopters, and other aircraft, as well as for satellites and other space-related equipment.

- Construction: Metal forming is used to create structural components for buildings and other structures, such as beams, columns, and girders.

- Manufacturing: Metal forming is used to create a wide range of machine parts, tools, and other equipment used in manufacturing, such as gears, shafts, and molds.

- Medical: Metal forming is used to create various medical devices, such as surgical and prosthetic devices.

- Consumer Goods: Metal forming processes creates a wide range of consumer goods, such as kitchenware, jewelry, and other household items.

- Defense: Metal forming processes is used to create a wide range of defense-related products such as weapons, armor, and other military equipment.

Altogether, metal forming is a flexible technique that may be utilized to make various products for various businesses. The unique application’s needs will determine the application technique and how the product is used. (Metal Forming Processes)

Conclusion

In conclusion, metal forming processes is a manufacturing process that involves shaping and reshaping metal into a desired shape or form. The process can be accomplished through various techniques such as stamping, forging, rolling, Extrusion, bending, drawing, and deep Drawing. Each of these techniques has unique advantages and disadvantages, and the best process for a given application will depend on the product’s specific requirements. Metal forming is used in various automotive, aerospace, construction, and manufacturing industries.

The process is versatile and efficient, allowing the creation of a wide range of products, from simple to complex, from small to large, and from low to high volume production. The manufacturer needs to have a good understanding of the process, materials, and equipment to achieve quality and efficiency in the final product.

Contact SJC Precision’s specialists right away for answers to your concerns.